Scag Check Engine Light Codes PDF: A Comprehensive Guide

Navigating Scag mower diagnostics involves understanding error codes, accessing PDFs, and utilizing resources like dealer networks and online forums for effective troubleshooting and repair.

Understanding Scag Mowers and Their Diagnostic Systems

Scag mowers, renowned for their durability and performance, employ sophisticated diagnostic systems to ensure optimal operation. These systems, integral to maintaining peak efficiency, rely on a network of sensors monitoring critical components like the engine, hydraulics, and electrical systems. When a malfunction occurs, the mower’s onboard computer registers a diagnostic trouble code (DTC), illuminating the check engine light.

Understanding these systems requires recognizing that Scag utilizes proprietary codes, necessitating specific diagnostic tools or resources for accurate interpretation. The evolution of these systems means code lists and procedures can vary based on the mower’s model year and series. Accessing detailed information, often found in PDF format, is crucial for technicians and owners alike to effectively diagnose and resolve issues, ensuring continued reliable performance from their Scag equipment.

The Importance of Check Engine Lights on Scag Mowers

The check engine light on a Scag mower isn’t merely an indicator; it’s a critical warning system signaling potential problems that, if ignored, can lead to significant damage and costly repairs. Addressing these alerts promptly prevents minor issues from escalating into major mechanical failures, preserving the longevity and performance of the mower.

Ignoring the light can result in reduced efficiency, increased fuel consumption, and even complete operational shutdown. Utilizing Scag’s diagnostic resources, including readily available PDF guides detailing error code interpretations, empowers owners and technicians to pinpoint the source of the problem. Proactive attention to these signals ensures continued productivity and minimizes downtime, safeguarding the investment in a high-quality Scag mowing machine.

Locating Scag Check Engine Light Codes

Finding Scag check engine light codes often begins with the mower’s onboard diagnostic system. Many newer Scag models display codes directly on the machine’s control panel. However, comprehensive code lists and detailed explanations are typically found within Scag’s official diagnostic PDFs and owner’s manuals.

These resources are frequently available through Scag’s dealer network or accessible online via Scag’s official website. Online forums and communities dedicated to Scag mowers also serve as valuable repositories of shared knowledge, where users often post and discuss specific code interpretations. Remember to always cross-reference information from multiple sources to ensure accuracy when diagnosing issues based on these codes.

Accessing Scag Diagnostic PDFs

Obtaining Scag diagnostic PDFs is crucial for effective troubleshooting. The primary source is the official Scag website, often requiring registration or access through a Scag dealer. These PDFs contain detailed code lists, diagnostic flowcharts, and repair procedures specific to each mower model and year.

Alternatively, Scag dealer networks provide direct access to these manuals, often as a complimentary service with a purchase or repair. Online searches can yield results, but verifying the document’s authenticity and relevance to your specific Scag model is paramount. Ensure the PDF is current, as Scag’s diagnostic systems and code definitions evolve over time. Always prioritize official Scag documentation for accurate information.

Common Scag Check Engine Light Code Categories

Scag check engine light codes generally fall into three primary categories: Engine Related, Hydraulic System, and Electrical System. Engine codes often indicate issues with fuel delivery, ignition, or sensor malfunctions impacting performance. Hydraulic codes signal problems within the mower’s hydraulic circuits, affecting lift, steering, or drive functions.

Electrical codes pinpoint faults in wiring, solenoids, or control modules. Within each category, codes are further refined to specify the exact component or circuit experiencing the issue. Diagnostic PDFs categorize these codes, providing a structured approach to identifying the root cause. Understanding these broad categories narrows down the troubleshooting process, saving time and effort.

Engine Related Codes

Engine related codes on Scag mowers frequently address fuel system inefficiencies, such as a faulty fuel pump or clogged fuel filter, impacting engine operation. Ignition system malfunctions, including a weak spark or defective ignition coil, also trigger codes. Sensor failures, particularly those monitoring engine temperature, oil pressure, or air intake, are common culprits.

Specific codes might indicate issues with the throttle position sensor, governing engine speed, or the crankshaft position sensor, crucial for timing. Diagnostic PDFs detail these codes, explaining potential causes like low compression or improper valve timing. Addressing these codes often involves inspecting and replacing components, ensuring optimal engine performance and preventing further damage.

Hydraulic System Codes

Hydraulic system codes on Scag mowers often point to low hydraulic fluid levels or contamination, impacting operational pressure and performance. Pump failures, characterized by reduced output or unusual noises, frequently trigger diagnostic trouble codes. Valve malfunctions, including solenoid issues or internal leaks, disrupt fluid flow and control.

Cylinder leaks, leading to decreased lift or movement, are also common causes, detailed within Scag’s diagnostic PDFs. Codes may indicate problems with the hydraulic filter, restricting flow, or issues with the hydraulic cooler, causing overheating. Resolving these issues typically involves fluid changes, component replacement, and thorough system inspection to restore optimal hydraulic function.

Electrical System Codes

Electrical system codes on Scag mowers frequently relate to battery voltage fluctuations, impacting starter and ignition systems. Faulty wiring harnesses, including damaged or corroded connections, disrupt power delivery and signal transmission, triggering diagnostic alerts. Sensor malfunctions, such as those monitoring engine temperature or oil pressure, provide inaccurate data, leading to incorrect operation.

Issues with the charging system, including a failing alternator or regulator, result in insufficient battery charging. Solenoid failures, affecting starter engagement or valve control, are also common. Scag’s diagnostic PDFs detail troubleshooting steps, often involving multimeter testing and component replacement to restore electrical integrity and reliable mower function.

Decoding Specific Scag Check Engine Light Codes

Decoding Scag check engine light codes requires referencing the specific diagnostic PDF for your mower model year. Codes aren’t universal; a ‘P0301’ code, indicating a cylinder one misfire, demands investigation of spark plugs, injectors, and compression. A ‘C1234’ code might signal a communication error within the CAN bus system, necessitating wiring harness inspection.

Scag’s documentation details each code’s potential causes and recommended troubleshooting steps. Often, codes point to multiple possibilities, requiring systematic testing. Utilizing a Scag diagnostic tool streamlines this process, providing live data and pinpointing the root cause. Remember, a code is a symptom, not the problem itself; accurate interpretation is crucial for effective repair.

Using a Scag Diagnostic Tool

Employing a Scag diagnostic tool significantly enhances troubleshooting accuracy. These tools connect to the mower’s diagnostic port, allowing access to real-time data, stored error codes, and system parameters. Beyond simply reading codes, they display engine RPM, hydraulic pressures, and sensor readings, aiding in pinpointing the source of the issue.

Modern Scag tools often feature built-in code databases and guided troubleshooting procedures, streamlining the diagnostic process. Some tools allow for component testing, verifying functionality without disassembly. Regularly updating the tool’s software ensures compatibility with newer Scag models and access to the latest diagnostic information. Referencing the tool’s manual alongside the Scag PDF is essential for optimal use.

Scag Self-Diagnostic Features

Many Scag mowers incorporate built-in self-diagnostic capabilities, offering a preliminary assessment before utilizing external tools. These features often manifest as flashing patterns of the check engine light, providing basic code indications. While less detailed than a dedicated diagnostic tool, these patterns can quickly identify major system failures – engine, hydraulic, or electrical.

Consulting the Scag operator’s manual is crucial for interpreting these flashing codes. Some models display numerical codes directly on the mower’s display panel. These self-tests are valuable for initial triage, helping determine if a professional repair or simple fix is needed. However, for comprehensive diagnostics and accessing detailed PDF information, a dedicated Scag diagnostic tool remains the preferred method.

Troubleshooting Based on Code Information

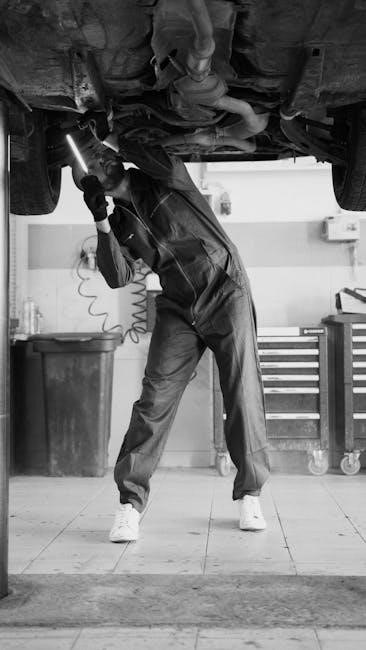

Once a Scag check engine light code is identified, systematic troubleshooting is essential. Begin by referencing the Scag diagnostic PDF or manual corresponding to your mower’s model and year. The code will pinpoint the affected system – engine, hydraulics, or electrical – and suggest potential causes.

Start with simple checks: fuel levels, wiring connections, and fluid levels. Then, progressively investigate more complex components based on the code’s description. For instance, an engine code might require checking the spark plug, air filter, or fuel injector. Always prioritize safety and disconnect the battery before working on electrical components. Detailed PDFs often include flowcharts to guide the troubleshooting process, ensuring a logical and efficient repair approach.

Resources for Scag Code Interpretation

Successfully interpreting Scag check engine light codes relies on accessing reliable resources. Scag Dealer Networks are invaluable, offering expert diagnostics and genuine parts. Their technicians possess specialized knowledge and access to the latest Scag diagnostic tools and PDFs.

Online Scag Forums and Communities provide a platform for owners and mechanics to share experiences and solutions. These forums often contain user-created code lists and troubleshooting tips, supplementing official documentation. However, verify information carefully. Additionally, dedicated websites specializing in small engine repair may offer code interpretations. Remember to always cross-reference information with official Scag manuals and PDFs for accuracy and safety when performing repairs.

Scag Dealer Networks

Scag dealer networks represent a crucial resource for accurate check engine light code interpretation and resolution. These authorized service centers employ certified technicians specifically trained on Scag mowers and their diagnostic systems. They have direct access to the most current Scag diagnostic PDFs, technical bulletins, and specialized tools required for precise troubleshooting.

Beyond code reading, dealers offer comprehensive diagnostic services, identifying the root cause of the issue, not just the symptom indicated by the code. They can perform thorough system checks, ensuring all components function correctly. Utilizing genuine Scag parts guarantees compatibility and maintains the mower’s performance and warranty. Contacting your local Scag dealer provides professional assistance and peace of mind when dealing with complex engine light issues.

Online Scag Forums and Communities

Online Scag forums and communities provide a valuable platform for owners and enthusiasts to share experiences and knowledge regarding check engine light codes. These digital spaces often host extensive threads dedicated to specific error codes, offering potential solutions and troubleshooting tips from fellow Scag mower users. Accessing these forums can supplement official Scag diagnostic PDFs and provide real-world insights.

While not a replacement for professional diagnosis, these communities can assist in preliminary investigations and offer guidance on common issues. Users frequently share their repair journeys, including diagnostic steps and part replacements. However, always verify information with official Scag documentation or a qualified technician to ensure accuracy and avoid potential damage. Remember to exercise caution and critical thinking when applying advice found online.

Scag Diagnostic Manuals and PDFs – Where to Find Them

Locating official Scag diagnostic manuals and PDFs is crucial for accurate interpretation of check engine light codes. The primary source is typically through authorized Scag dealers, who can provide the latest versions tailored to specific mower models and years. Scag’s official website may also offer downloadable resources, though access might be restricted to registered dealers or require a purchase.

Third-party websites sometimes host older versions of these manuals, but verifying their accuracy is essential. Ensure the PDF corresponds to your mower’s model number and production date. These manuals contain detailed code definitions, troubleshooting procedures, and wiring diagrams. Utilizing the correct documentation prevents misdiagnosis and ensures repairs are performed safely and effectively, maximizing the longevity of your Scag mower.

Preventative Maintenance to Avoid Check Engine Lights

Proactive maintenance significantly reduces the likelihood of triggering Scag mower check engine lights. Regularly scheduled servicing, including oil and filter changes, air filter replacements, and fuel system cleaning, maintains optimal engine performance. Inspecting and maintaining the hydraulic system – checking fluid levels and hoses – prevents related error codes.

Electrical connections should be inspected for corrosion and tightness, as faulty wiring often causes diagnostic trouble. Keeping the mower deck clean and free of debris minimizes strain on the engine. Adhering to Scag’s recommended maintenance schedule, outlined in the owner’s manual, is paramount. Consistent preventative care not only avoids costly repairs but also extends the mower’s lifespan and operational efficiency.

Resetting the Check Engine Light After Repair

After addressing the issue indicated by a Scag check engine light code, properly resetting the system is crucial. While some newer Scag models feature automatic reset functionality upon code correction, many require manual intervention. This often involves accessing the diagnostic menu through the mower’s control panel, utilizing a Scag diagnostic tool, or disconnecting the battery for a specified duration – consult your owner’s manual for the precise procedure.

Verify the repair before resetting; simply clearing the code without fixing the underlying problem will result in its recurrence. Post-reset, monitor the mower’s performance to confirm the issue is resolved and the check engine light remains off. If the light reappears, further diagnostics are necessary.

Understanding Scag’s Error Code System Versions

Scag’s diagnostic system has evolved over the years, resulting in variations in error code formats and interpretations across different mower models and production years. Older models may utilize a simpler, numerically-based code system, while newer machines often incorporate more complex alphanumeric codes providing greater specificity. Accessing the correct diagnostic information – including relevant PDFs – requires knowing your mower’s specific year and model.

Furthermore, software updates can sometimes alter code definitions. Therefore, relying on outdated manuals or online resources may lead to misdiagnosis; Always prioritize documentation specifically tailored to your Scag mower’s configuration to ensure accurate interpretation and effective troubleshooting.

Limitations of Using Only Code Information

While Scag check engine light codes offer a valuable starting point for diagnosis, relying solely on them can be misleading. A single code often indicates a symptom rather than the root cause of the problem. Multiple factors can trigger the same code, necessitating a thorough investigation beyond simply replacing the component directly associated with the error.

Environmental conditions, operator technique, and the overall condition of the mower all play a role. Diagnostic PDFs provide code definitions, but they cannot account for unique circumstances. A skilled technician will combine code information with physical inspection, system testing, and a comprehensive understanding of Scag mower operation for accurate repairs.

Future Trends in Scag Diagnostic Technology

The future of Scag mower diagnostics points towards increasingly sophisticated, integrated systems. Expect more advanced onboard diagnostics offering real-time data streaming and predictive maintenance alerts, accessible via mobile apps and cloud platforms. Enhanced self-diagnostic features will pinpoint issues with greater accuracy, reducing reliance on manual code interpretation and PDF guides.

Integration with telematics will allow remote monitoring of mower performance, identifying potential problems before they lead to downtime. Artificial intelligence and machine learning algorithms will analyze diagnostic data, providing technicians with targeted repair recommendations. Wireless updates to diagnostic software and code libraries will ensure technicians have the latest information at their fingertips, streamlining the repair process.